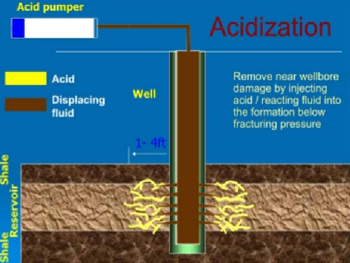

Acidizing is one of the oldest techniques in good stimulation processes still being used today. Acids play a key role in boosting production or increasing injectivity in oil and gas fields. Modern acid stimulation systems can be controlled and targeted to achieve specific aims for the asset team. In the case of treating formation damage, acid removes flow-restricting particles, scale deposits, and minerals in the reservoir or in the immediate wellbore vicinity. The acid mixture holds the dissolved substance in solution until it is either removed from the well system or overflushed a safe distance into the formation; then, the well can produce at its natural potential. Matrix stimulation involves pumping acids, solvents, or other treatment chemicals into the formation at less than the reservoir fracture pressure. Matrix stimulation methods can be applied in clastic or carbonate rocks. It is designed to remove or bypass damage in the pore spaces and to leave the zone barriers intact. In sandstones, matrix treatments are used to restore or

improve the natural formation permeability around the wellbore by removing formation damage. This is accomplished by dissolving material that is plugging the pores or by enlarging the pore spaces. In carbonates, matrix stimulation creates new, highly conductive channels (wormholes) that bypass the damage. Because of these different requirements, the selection criteria for the treating fluid are also distinct. For sandstone rocks, it is vital that the stimulation engineer understands the extent, type, location, and origin of the damage, the reservoir mineralogy, and the compatibility of the treating fluid with the formation. In carbonate treatments, reservoir temperature, pumping rate, and fluid type become more significant because these parameters have a direct influence on the reaction between the treating fluid and the reservoir rock.

Top Select stimulation team, having numerous experiences in matrix acidizing services, is ready to provide your esteem company with qualitative technical proposal and the service.